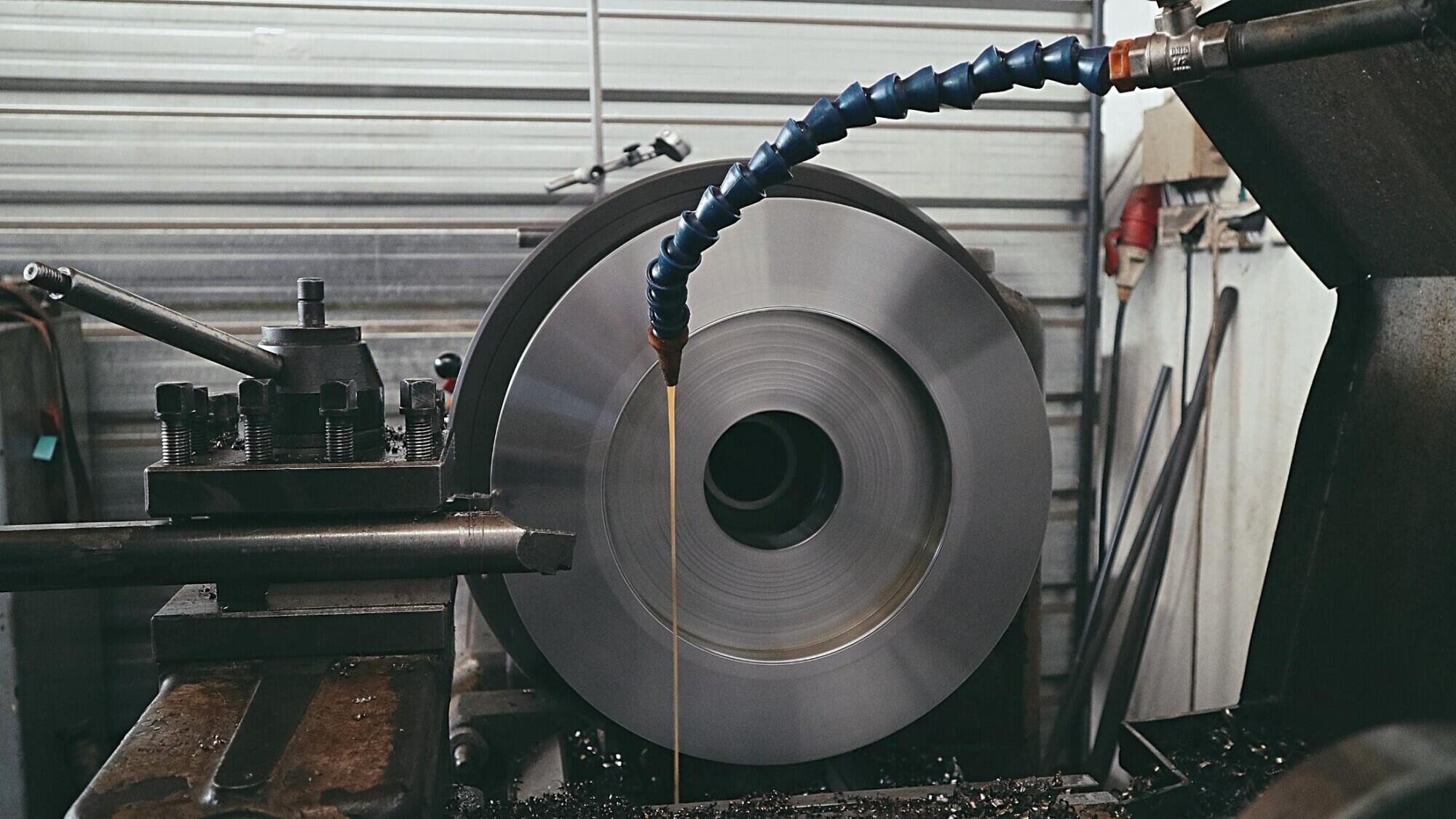

The Advantages and Applications of Centerless Grinders

The manufacturing industry is changing a lot because of centerless grinders. Unlike traditional grinding machines, they offer the highest level of accuracy with the least amount of setup time.

The main benefits of centerless grinders are talked about in this article. Find out what makes them different, from higher accuracy to higher efficiency.

We will also talk about different applications that show how flexible they are. Find out why centerless grinders are so important, whether you’re a seasoned manufacturer or new to the business.

Help us figure out how centerless grinding process optimization can be used in modern manufacturing. Continue reading!

Unrivaled Precision and Consistency

Centerless grinding stands out because it’s super precise and consistent. Imagine grinding something without having to hold it in place like usual.

Instead, it’s supported by wheels as it gets ground. This cool method gets rid of mistakes usually made when trying to hold things steady, making sure everything is grounded just right.

Enhanced Efficiency and Productivity

Centerless grinding machines make production smoother and faster by letting parts be ground non-stop. This cuts down on waiting times and makes things more productive. These machines are perfect for making lots of parts quickly and accurately, saving time and effort.

Versatility Across Materials and Sizes

Centerless grinders are flexible tools. They can work with many materials, like metals and plastics, and handle different sizes too. Whether you’re working on a tiny detailed piece or a big rough one, these machines can easily adjust to what you need.

Reduced Labor Requirements

Centerless industrial grinding is a cool tech that automates the grinding process, cutting down the need for people to constantly check on it. This means it saves on the costs of needing a lot of workers. Plus, one person can oversee several machines at once, making the whole production line smoother and more affordable.

Superior Finishing and Aesthetic

Centerless grinders are great at making surfaces look and feel smooth and nice. They’re perfect when you want something to look good as well as work precisely. They grind gently, so the result is both smooth to the touch and easy on the eyes.

Minimal Part Damage Risk

Centerless metalworking equipment grinders are designed to protect parts from damage when precision grinding. Unlike other machines, these don’t clamp the workpiece.

Instead, they use a grinding and a regulating wheel to support it. This reduces the risk of bending or distorting the part, making it safe to precisely grind delicate pieces.

Applications of Centerless Grinders

Centerless grinding machines are versatile tools used in many industries for their precision. In the automotive world, they make precise parts like axles and pins.

The aerospace industry uses them to perfect turbine blades and other vital parts. They’re even used in creating everyday household items and making things accurately and efficiently.

When we talk about what makes centerless grinders so great, we have to talk about the Cincinnati Centerless Grinder Machine. It’s super efficient and reliable, showing off the latest tech in centerless grinding.

The Future Shines Bright with Centerless Grinders

Centerless grinders are a big step forward in making things precisely and efficiently. Their special design helps produce consistent, high-quality items for many industries.

These machines save money by cutting labor costs and reducing the chance of damaging parts. They can work with different materials and sizes, showing how versatile they are.

Adding centerless grinders into production lines is changing the future of how things are made. This innovation is a major leap in the technology used for manufacturing.

Did you like this guide? Great! Please browse our website for more!