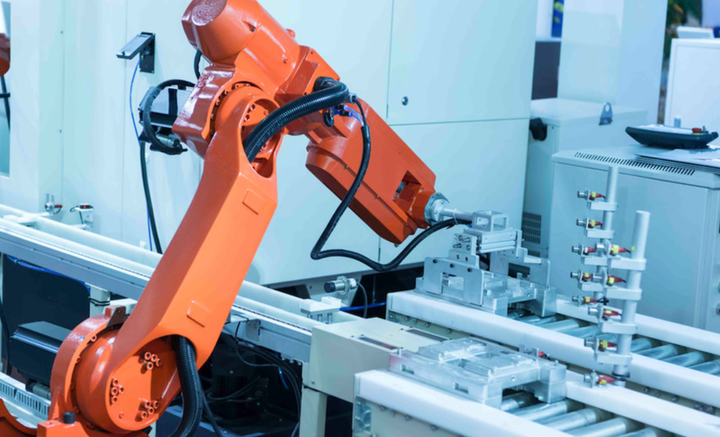

The Role of Robotics in Manufacturing Efficiency

In the manufacturing field, regardless of the industry robotics has always enhanced the systems. Robotics in production and processes has been advanced for the past few years. Technology has always skyrocketed the human race’s growth.

But after the integration of robotics, the technology has taken the upper hand in this matter. This all happened due to certain reasons. Here I have researched some of the potential reasons for the manufacturing efficiency that happened with the help of robotics.

Error Prone and Precision

Robotic arms and machines do as per instructions. This leads to an error-free and perfect product as a result. This way, the best products, and machinery are delivered. Venty Vaporizer is one of the best vaporizers in the market today. If you want to know more about Venty Storz Und Bickel Test, visit Venty vaporizer link. Without, robotic arms and machinery products did get produced but at an intermediate speed and with a risk of error. In this way, robotics has enhanced the precision which ranks best in the favor of the manufacturing era.

Workplace Safety

For chemical production or a highly physical workload, robots are the best option. Minimize accidents and damages, this leads to safer work zones. This is very essential for the employees as robots do all the hard work. Apart from this, the labor or employees are saved from industrial accidents and production loss. All extreme work can now be laid on the robotics arms.

Expectioanl Productivity

With no medical leaves, shift change schedules, and no breakdowns, robots are the perfect replacement for long, tiring, and non-stop manufacturing processes. This leads to a faster and more significant boost in the production line. With increased productivity, the finances are boosted and other employees can provide their services in other sectors of the industry.

Easily flexible and Quick Adaptability

Unlike humans, robots don’t require training and on-the-job practices to get used to the system. Just set up the requirements on the robot’s control panel and production is ready to start. Moreover, the adaptability chances are 100% as they require no time to adjust and reset their job practices. This also saves technicians a lot of workload and sessions of training.

Cost Efficient

Robotic machinery is expensive and quite heavy on the financial bill. But this all is for the short term. In the coming years, these robotics machineries will save time, money, and also lives. With little maintenance and timely sessions, the machines perform quite well. This leads to saving a lot of money in insurance and cost-cutting.

Robotics is one of the best technological changes that ever happened in the manufacturing industry. But the advancement doesn’t stop in this era, the advancement, and emerging technologies are pushing robotics to a higher level. Looking forward to the near future, the human race has a lot to see in the manufacturing industry. Please check out VentyTest.com for more information.